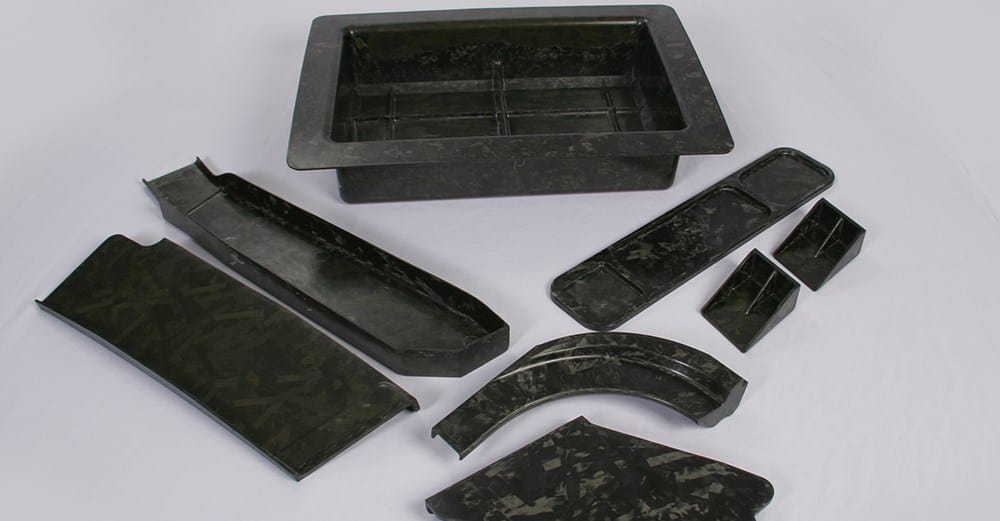

HexMC® is a high performance molding material, suitable for the production of complex shaped parts and specifically designed for compression molding.

With long carbon fibers (50mm) and a low resin content, HexMC® provides better mechanical properties than any other short or long fiber molding compound.

HexMC® molding materials enable composite parts to be manufactured for:

- Applications where complex 3-D shapes limit the use of typical fiber reinforced matrices/reinforced laminated composites;

- Use for applications where previously metal was the only solution;

- Parts with abrupt change of cross-sectional thickness;

- Applications where co-curing of elements is desired, such as metal inserts or mixing with other materials and more.

- Use with automated production process similar to SMC molding;

- Production of parts with zero material waste.

HexMC® Aerospace Grade

HexMC® enables complex shapes to be manufactured in cost-effective series production while providing weight savings that are comparable to those traditionally achieved with aerospace carbon/epoxy prepregs. The resulting weight-savings reduce fuel consumption and increase aircraft payload.

HexMC®-i Industrial Grade

For industrial applications the HexMC®-i epoxy resin system cures in a short cycle – from 2 minutes at 150°C depending on part thickness. Complex shapes can be achieved and inserts can be integrated during the molding process. HexMC®-i is particularly beneficial for sporting goods, automotive and marine applications, as well as a wide range of industrial components.

For all industrial and non-aerospace applications please contact:

- javier.munoz@hexcel.com (Europe)

- john.pruett@hexcel.com (USA)

Technical Resources

Molding Compound

| Products | Description | Downloads |

|---|---|---|

| HexMC M77 | User Guide | |

| C/2000/M77-RA | Carbon Epoxy Molding Compound | Global Version |