Parts & structures

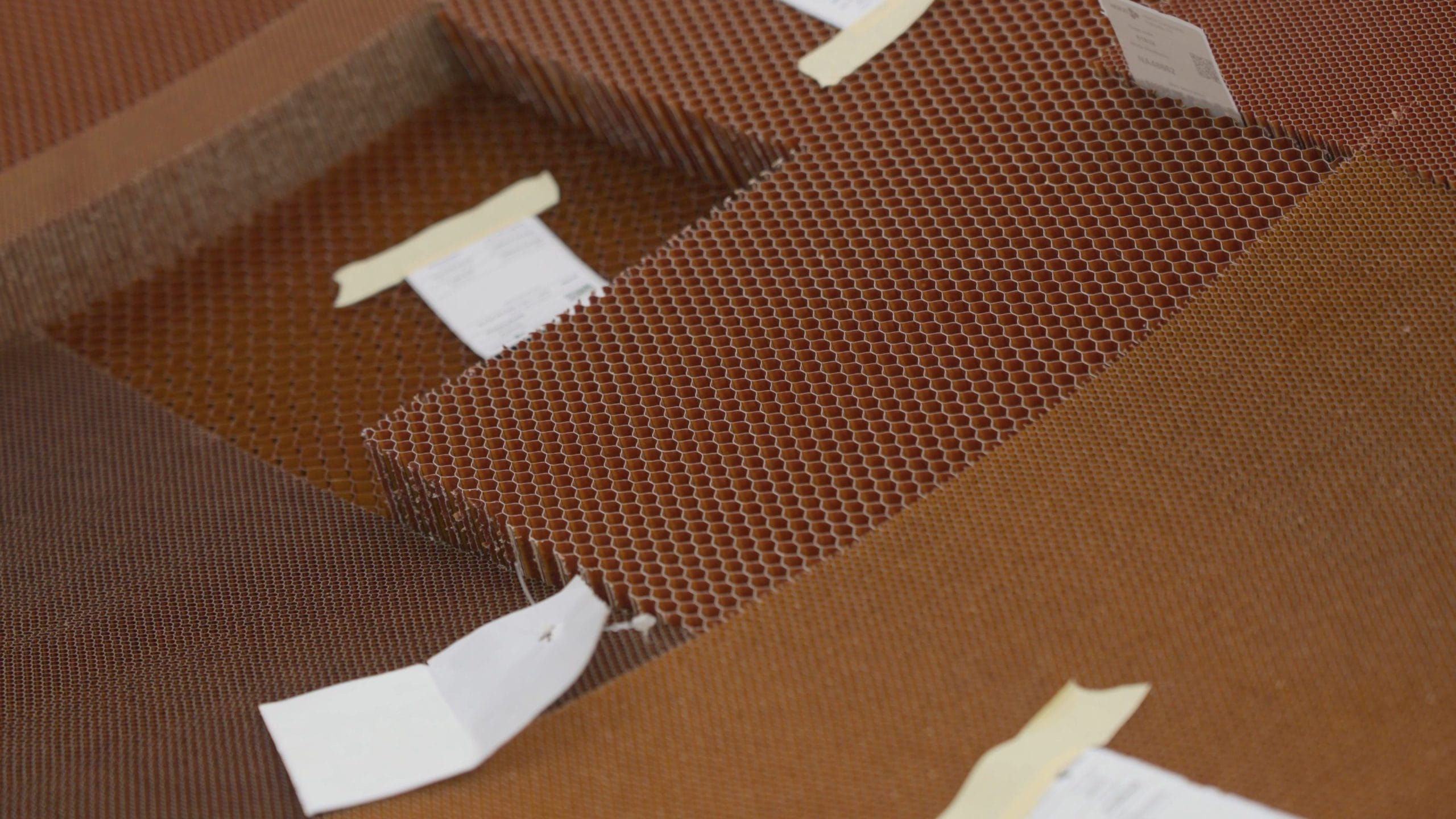

Composite Structures

Hexcel manufactures and markets lightweight, high-strength composite structures and assemblies for commercial and military fixed wing aircraft, helicopters, business jets, UAVs, and spacecraft. We have a history of documented performance for aerospace and defense contracts, working for Airbus, Boeing, Bombardier, Mitsubishi Heavy Industries, Sikorsky, Kawasaki Heavy Industries, SpaceX, Blue Origin, and Lockheed Martin.