Aerospace Composite Materials for Every Section of the Aircraft

Fabrics and Reinforcements

Prepregs and Resins

Adhesives

Honeycomb

Tooling

Parts and Structures

RF Interference Control

Trusted by the World’s Leading Aerospace Manufacturers

Hexcel is a major supplier of composites for primary and secondary structures, aircraft interiors – and a leader in composites for new generation engines.

Commercial Aerospace

The composites content in each new aircraft program has grown significantly since the introduction of prepregs in the 1970s. Composites are now essential materials in the construction of all aircraft and the commercial aerospace industry is the largest user of Hexcel advanced composites.

In new wide bodied aircraft such as the Boeing 787 and the Airbus A350 XWB composites account for over 50% of the airframe. Hexcel was proud to be awarded the contract by Airbus to supply HexPly® prepreg reinforced with HexTow® carbon fiber for all composite primary structures of the A350 XWB.

The Boeing 737 MAX engine nacelles have an acoustic inner barrel that is manufactured from Hexcel engineered core and benefits from Hexcel’s Acousti-Cap® technology in which a permeable cap material is individually embedded into each honeycomb cell to create an acoustic septum. This technology is a leading contributor to the reduction of the area of acceptable noise contour of the 737 MAX engine by 40% over the legacy 737 NG, without any weight penalty.

Why use Hexcel composites?

Hexcel’s composite materials bring great benefits to aircraft design. They save weight and reduce fuel consumption, increase payload, extend flight range, enhance toughness and durability, optimize design, reduce part count, decrease maintenance cost and maximize passenger comfort and safety. The improvement in fatigue performance with carbon fiber reinforced prepregs (CFRP) compared to aluminum is also a major benefit.

Products for Aerospace

With a spirit of innovation that has grown stronger and stronger for over 75 years, Hexcel continues to push back the performance boundaries for aircraft designers with IM carbon fiber, toughened epoxy resins, out-of autoclave curing prepregs, noise reducing honeycombs and value added composite parts.

- Carbon Fibers: HS, IM and HM

- Carbon, Glass, Aramid and other Fiber Woven Fabrics

- Prepregs

- Adhesives

- High performance HiTape® and HiMax® dry carbon reinforcements and liquid resins for structures made by infusion technologies (out of autoclave)

- Honeycomb and Engineered Core Composite Structures, including Acousti-Cap®

- Composite tooling compound : HexTool®

Commercial Aircraft

Hexcel has the greatest number of aerospace qualified products of any composite materials manufacturer worldwide.

Hexcel’s composite materials bring great benefits to aircraft design. To save weight and reduce fuel consumption, increase payload, extend flight range, enhance toughness and durability, optimize design, reduce part count, decrease maintenance cost and maximize passenger comfort and safety. The improvement in fatigue performance with carbon fiber reinforced prepregs (CFRP) compared to aluminum is also a major benefit.

More than 50% of the Boeing 787 and the Airbus A350 XWB airframes are carbon fiber composite. Hexcel is a major supplier of materials to both programs and was awarded the contract by Airbus to supply the primary structure prepreg, with Hexcel carbon fiber, for the A350 XWB program.

Hexcel is a major supplier of composites for primary and secondary structures, aircraft interiors – and a leader in composites for new generation engines.

With a spirit of innovation that has gone from strength to strength for more than 65 years, Hexcel continues to push the performance boundaries for aircraft designers with IM carbon fiber, toughened epoxy resins, out-of-autoclave curing prepregs, noise-reducing honeycombs and value-added composite parts.

- Carbon Fibers HS, IM or HM

- Carbon, Glass, Aramid and Other Fibers Woven Fabrics

- Prepregs

- Adhesives

- High performance HiTape® and HiMax™ dry carbon reinforcement and liquid resins for structures made by infusion technologies (out-of-autoclave)

- Honeycombs and Engineered Core Composite Structures, including Acousti-Cap®

- Moulding compound : HexTool® for tooling, and HexMC® for aircraft parts

Aerospace Resources

SELECTOR GUIDES

- HexTow® Carbon Fiber Selector Guide

- HexPly® Prepregs and HexForce® Reinforcements for Aerospace

- Redux® Adhesives Selector Guide

- HexForce® US fabrics handbook

TECHNOLOGY MANUALS

- Prepreg Technology

- Direct Processes Technology Manual

- Composite Repair

- Redux® Bonding Technology

- HexWeb® Honeycomb Attributes and Properties

- Honeycomb Sandwich Design Technology

- Sandwich Panel Fabrication Technology

- HexTool®

BROCHURES

- HexWeb® Acousti-Cap®

- HexWeb® Engineered Core

DATA SHEETS

- Engineered Core and Acousti-Cap®

- Carbon Fibers

- Reinforcements – U.S. range

- Reinforcements – EU & U.S. range

- Prepregs

- Infusion Resins

- Honeycombs

Engines and Nacelles

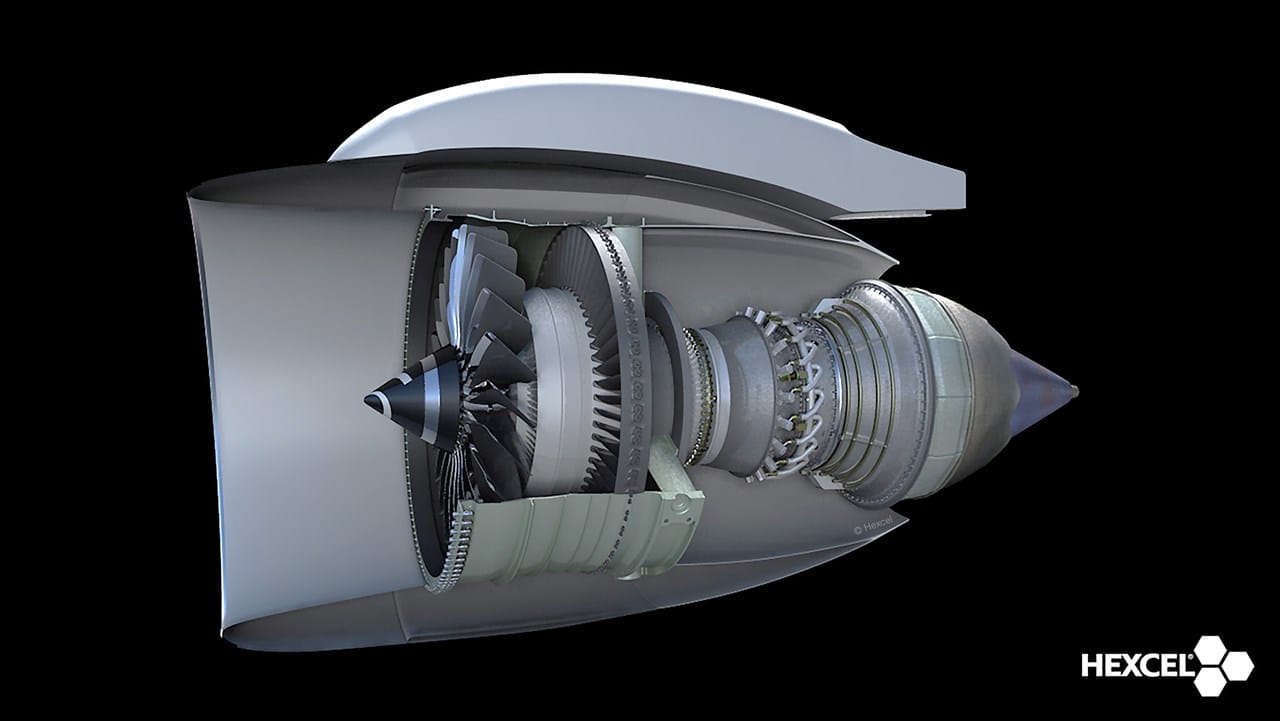

Aircraft engines have evolved to include so many major composite components that carbon fiber epoxy prepregs account for typically half the volume of the entire nacelle structure. The next step for aero engine designers has been to apply composites technology to more complex structures within the engine itself. Hexcel’s proven sound attenuating treatment for our honeycomb core, called Acousti-Cap®, has been proven to quiet jet engine noise more effectively than any competing system and has been specified on the Boeing 787 and 737 MAX nacelles. Our unique capability to weave carbon on a 45-degree bias helps customers reduce scrap. Our toughest carbon fiber prepreg system is used for the front fan blade on the GEnx engine and our HexTow® carbon fiber is used on the LEAP Engine fan blades and casing.

Recommended Products

- HexTow® HS (AS4) and IM (IM7/IM8) carbon fibers for high strength and toughness

- HexPly® 8552 and M21 toughened epoxy prepregs

- HexPly® M91 high strength, damage-resistant prepreg ideal for fan blades

- HexPly® M65 BMI prepregs with long service life at high temperatures

- HexFlow® RTM6 system for Resin Transfer Molding

- HexWeb® HRH-36 high performance and low weight aramid paper honeycomb

- HexWeb® HDC high density core

- HexWeb® HRP fiberglass/phenolic honeycomb

- HexWeb® CR-PAA high bond strength honeycomb with corrosion protection

- HexWeb® engineered core honeycomb parts supplied to tight dimensional tolerances

- HexWeb® Acousti-Cap® broadband noise reducing non-metallic honeycomb

- HexWeb® Acousti-Cap® aluminum broadband noise reducing honeycomb – a lower cost version of the award-winning non-metallic system

- Redux® high performance temperature-resistant epoxy and HP655 BMI adhesive in film form

- HexFlow® RTM6-2 – a 2-part version of standard HexFlow® RTM6 for ease of transportation outside Europe

- HexFlow® RTM230 ST, a high toughness epoxy system to meet demanding high speed impact requirements for guide vanes

- HiMax™ multiaxials and HiTape dry UD offering design flexibility for OOA infused/injected components

- HexForce® Bias Weave fabric – a patented weaving process reducing scrap by up to 30%

- HexMC® carbon fiber molding material – for rapid manufacture of profiled parts in automated production, e.g. Guide vane parts

Composite Repair

Prepreg repair solutions for aerospace structures

HexPly® M20 Prepreg for Composite Repair

In the early 1990s, Hexcel was asked by the newly formed Composite Aircraft Composite Repair Committee (CACRC) to develop a prepreg repair solution for Aerospace structures. Hexcel proposed an epoxy prepreg with a high-temperature performance from a low energy cure cycle. HexPly® M20 prepreg cures at 130°C (265°F) to form a tough, high temperature resistant fiber-reinforced composite.

Compared to wet lay-up repair systems, prepreg provides a cleaner, more efficient, and controllable process.

Through the CACRC qualifications, HexPly® M20 offers a harmonized product across multiple OEMs for airlines to purchase and stock for all their fleet repair needs.

Availability

Hexcel can support direct materials supply at the MOQ level. For requirements lower than MOQ, materials are available through the approved repair distribution outlets:

Composite Distribution, BP 30044 01120 Dagneux, (France)

Contact: Patrick Renard; Tel: + 33(0)4 72 25 26 86

Email: patrick.renard@composites-distribution.com

HEATCON® Composite Systems, 480 Andover Park East, Seattle, WA 98188

Contact: Clint Millett; Tel: 206-575-1333

Email: cmillett@heatcon.com

Urban Air Mobility (UAM) / Advanced Air Mobility (AAM)

NEWS: Archer Plans to Work With Hexcel to Advance Production Capabilities

FEATURE: The Dawn of Urban Air Mobility Comes at Midnight

VIDEO: Hexcel and Archer: Delivering a Safe, Reliable eVOL Platform to Market

Urban Air Mobility (UAM), or Advanced Air Mobility (AAM), is an emerging market that promises to be the next big transportation innovation. Similar to taxis or ride-sharing today, UAM/AAM will deliver transportation in the air, removing congestion from streets and providing a convenient and rapid method to travel within urban centers and deliver people and cargo to under served areas. Hexcel’s composite materials are the ideal solution to provide efficient, reliable, and cost-competitive transportation vehicles.

Hexcel offers an extensive line of carbon fiber solutions, including a range of HexTow® high modulus and high strength carbon fibers, which offer exceptional stiffness-to-weight performance critical for unmanned aerial vehicle (UAV) structural applications. These fibers are part of an extensive line of materials including epoxy matrix materials for standard autoclave cure, out-of-autoclave cure, quick cure, and infusion that are offered in woven fabric, unidirectional sheet, and tape form. Thermoplastic matrix systems are available that offer many processing, manufacturing, and repair advantages.

The UAM/AAM market will require solutions with the reliability of aerospace vehicles but with the high-rate producibility of the automotive market. Hexcel’s advanced composite solutions answer both criteria. Hexcel has long been well known and qualified on an extensive list of aerospace programs. Manufacturing of Hexcel composites can be automated, reducing production costs per part and increasing production volumes. HexFlow® and HiFlow™ infusion resins in combination with our HiTape® and HiMax® reinforcements can be used where large, integrated structures need to be created with dry fiber preforms and then infused and cured in a single operation.

Our advanced materials make UAM/AAM structures not only stronger and lighter but also more comfortable for the consumer. Our HexWeb® honeycomb core and Acousti-Cap® solutions help to dampen noise and vibrations from engines for a smooth and quiet ride.

Hexcel’s advanced materials can contribute to the electromagnetic properties of UAM/AAM systems that require efficient and reliable communication with ground stations or other UAM/AAM vehicles through wireless or satellite communications. Hexcel materials can be tuned to absorb certain electromagnetic frequencies and pass other frequencies. They are used for radomes that protect the transmit and receive antennas, and the radome materials and structure can be engineered to allow for efficient communication while blocking out signals that are coming from other sources.

Additional article on composite materials for UAM/AAM